223 Weld Size and Length. A weld joint is the junction of the edges or surfaces of parts that have been joined by welding.

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

One of the most important welding symbols is the fillet weld.

. The joint design selected will of course dictate what type of weld is to be made. 21 2022 at 1159pm. This chapter describes the fundamentals of weld joint design including the parameters that are obtained after designing a weld joint.

222 Joint Welding Sequence. A type of welding that is generally limited to thin materials high-integrity joints or small parts because of its low welding speed and high cost of equipment and materials. Chapter Outline Shigleys Mechanical Engineering Design.

Welding Joint Design and Welding Symbols. Sketch a weld on plates in the 1G and 1F positions. The weld joint is where two or more metal parts are.

1 types of joints and 2 the types of welds used to join the pieces that form the. Modes of failure rigidity and stiffness loading condition welding symbol type of weld and weld joint 221 Introduction Weld joints may be subjected to variety of loads ranging from a simple tensile. Chapter 9 Welding Bonding and the Design of Permanent Joints.

The overview of the joining. Welding symbols and their components are created using the same units the drawing in which they are displayed. Contents Preface Features of the Text Acknowledgments About the Author Index of Experiments and Practices Section 1 Introduction Chapter 1 Introduction to Welding Chapter 2 Safety in Welding Section 2 Shielded Metal Arc Welding Chapter 3 Shielded Metal Arc Equipment Setup and Organization Chapter 4 Shielded Metal Arc Welding of Plate Chapter 5 Shielded Metal Arc.

Terms in this set 14. 1 101006 WFP 2-04 AWS D11 Structural Welding Steel and other discontinuities that would adversely affect the quality or strength of the weld. Welding Principles and Applications Fifth Edition Larry Jeffus Australia Canada Mexico Singapore Spain United Kingdom United States.

A lap joint is where one plate lays on top of another plate. JS11 Joint Design Welding Symbols Student Handout for. Chapter 3 Welding Joints Positions and Symbols Learning ObjectivesAfter studying this chapter you will be able to.

Welding Symbols Arrow side of a joint is the line. This section covers two classifications related to weld joints. The correct joint design will then need a weld deposited to the highest quality possible at the lowest possible cost.

Your assignment this week is to draw out welds on plates using 6010 and 7018 rods in different positions. Read welding symbols and weld various types of joints using the proper weld-. It explains various aspects of welding processes.

Number of components being fabricated. ButtThis is a joint where two plates are butted together edge to edge. Be creative and detailed on your drawings.

Welding Principles and Applications is a stunning handbook on the applications and principles of weldingLarry Jeffus has authored the book and dedicated it to his daughters Wendy and Amy. Demands of the welding position. Advancing rapidly from basic concepts and processes to todays most complex cutting-edge welding technologies and practices this comprehensive text features valuable information on topics such as welding metallurgy metal fabrication weld testing and inspection joint design job costing and environmental and conservation tips.

The welded joint will occur at the edge of the top plate. Chapter 18 Activity. Engineering Standards Manual ISD 341-2 Chapter 13 Welding Joining Volume 2 Welding Fabrication Procedure Rev.

Plug and slot welds Other types of welds include. This symbol is characterized by a right triangle which is the lateral shape of a real fillet weld. Introduction Shigleys Mechanical Engineering Design Welding is the process of joining two pieces of metal together by hammering pressure or fusion.

Contract design drawings shall specify the effective weld length and for partial. Fillet welds are generally performed on a 90 degree joint of 2 perpendicular pieces of metal. And of The The.

Availability of suitable welding consumables. 11822 12122 Drawings are due on Friday Jan. 292 THE WELD JOINT Welding produces a solid connection between two pieces called a weld joint.

Welding Joint Design Welding Symbols and Fabrication. Chapter 1- The Welding Inspector 6 Terms. Experiments allow readers to develop new hands-on skills while gaining an understanding of the parameters of each welding process discussed in the book.

Module 4 Welding Design Heat Flow 1-D Conduction with Mass Movement Applying conservation of energy to the control volume Adx QAdx q A q A CV A CV A t C x x dx x x dx ρ θ ρ θ θ ρ 4-18 Using Taylor series expansion and simplifying x CV x q Q t C x θ ρ θ ρ Using Fouriers Law of Conduction x CV x Q t C. Plastic and Other Nonmetallic Fabrication Techniques Appendix Bilingual Glossary Index. Division 1 contains mandatory and non-mandatory appendices detailing supplementary design criteria nondestructive examination and inspection acceptance standards.

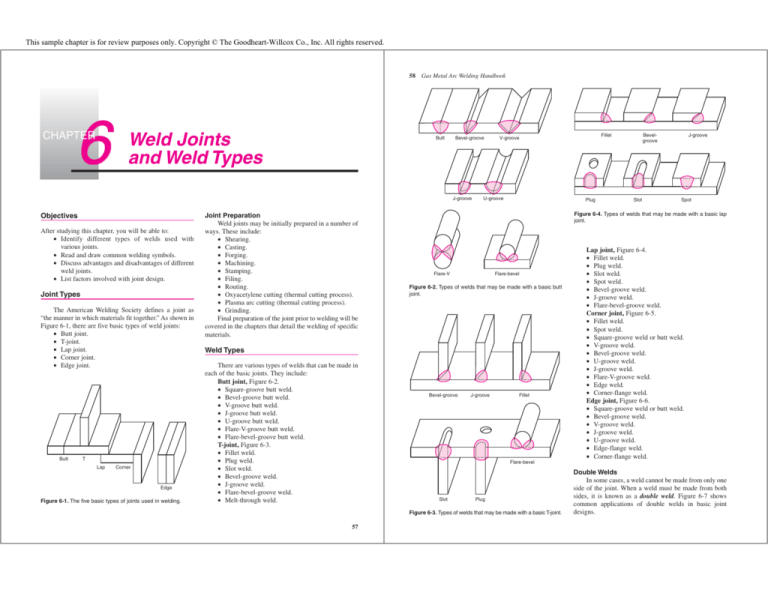

Identify and describe the various welds that may be used in each welding joint. Welding Process Major effect on selection of joint design Each welding process has characteristics that affect its performance Some processes are easily used in any position Others may be restricted to one or more positions Rate of travel penetration deposition rate and heat input also affect welds. Label the parts or areas of a.

There are three basic types of welds. Rules pertaining to the use of the single ASME certification mark with the U UM and UV designators are also included. Welding in chapter 7.

Cost of the process including capital expendi-tures materials and labor. Welding Joint Design Welding Symbols and Fabrication Chapter 18. Drawings of those joints or groups of joints in which it is especially impor-tant that the welding sequence and technique be carefully controlled to minimize shrinkage stresses and distortion shall be so noted.

Arc spot and seam welds Edge welds Flange welds Surfacing welds Seal welds. To fabrication methods such as welding forging and brazing. American Welding Society- CWI Welding Inspection Technology Chapter Examination 2008 146 Terms.

The book is valuable and beneficial for anyone especially for students. Welding Symbols Welding symbols are defined by the American Welding Society in ANSIAWS A24 Standard Symbols for Welding Brazing and. Basic Types of Welds.

This weld is an extremely common practice in fabrication and field work. A T joint is a joint where two metal plates are at a 90 degree angle and one of the pieces connects away from the edge. Identify the five basic welding joints.

Weld Joints And Weld Types Goodheart

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Welding Symbols And Welding Joint Design Youtube

Welding Symbols Mcgraw Hill Education Access Engineering

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Welding Joint Design And Welding Symbols Ppt Video Online Download

0 comments

Post a Comment